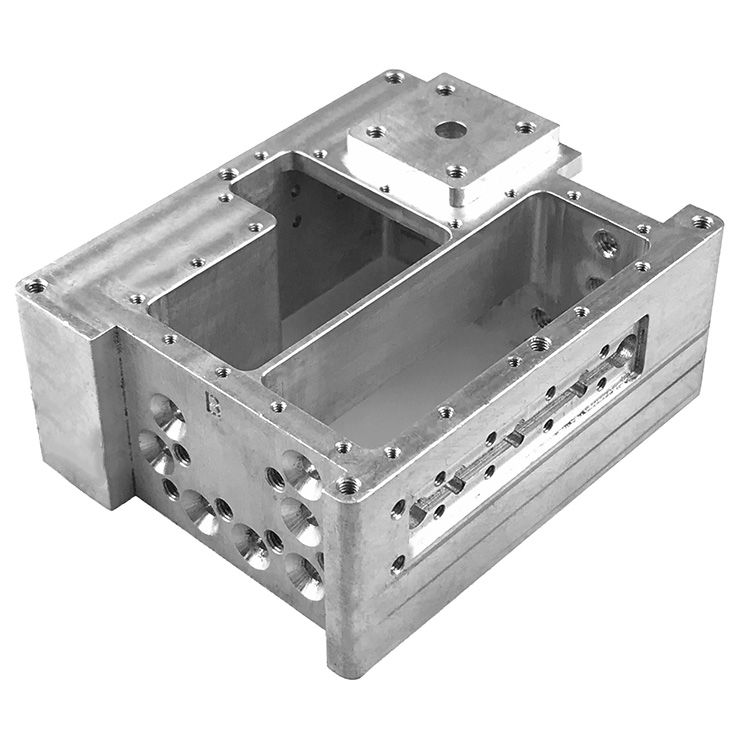

CNC Machining Magnesium Alloy Medical Parts

What are the benefits of using magnesium alloy for CNC processing of medical devices

Magnesium alloys have multiple benefits in CNC machining of medical devices, which can make them an attractive material choice for manufacturing medical equipment and instruments. Here are some benefits of using magnesium alloys for CNC machining of medical devices:

1.Lightweight: Magnesium alloy is a very lightweight metal with a lower density than many other engineering metals, such as aluminum and steel. This makes medical devices made of magnesium alloy lighter, easier to carry and use.

2.High strength: Despite being lightweight, magnesium alloy still has excellent strength, making it possible to manufacture sturdy and durable medical devices. This is particularly important for equipment that requires repeated use and disinfection.

3.Biocompatibility: Magnesium alloys have good biocompatibility, which means they are unlikely to cause adverse reactions when in contact with human tissues. This is very important for manufacturing implantable medical devices, such as implanted organs and orthopedic implants.

4.Corrosion resistance: Magnesium alloys typically have good corrosion resistance, which is crucial for medical devices as they may require frequent exposure to moisture, liquids, or disinfectants.

5.CNC machining performance: Magnesium alloys perform well in CNC (computer numerical control) machining, are easy to cut and process, and are therefore suitable for complex tool and component manufacturing. This helps to manufacture high-precision medical devices.

6.Thermal conductivity: Magnesium alloys have good thermal conductivity, which is important for the performance of certain medical devices, such as heat sinks in electronic devices.

It should be noted that magnesium alloys also have some challenges, such as their susceptibility to oxidation at high temperatures, so measures need to be taken to protect the surface. In addition, the manufacturing process may require special engineering techniques to ensure the quality and consistency of the alloy. However, for medical device manufacturers, it is often reasonable to balance these challenges with the advantages of magnesium alloys, as they can provide key features such as lightweight, strength, and biocompatibility.