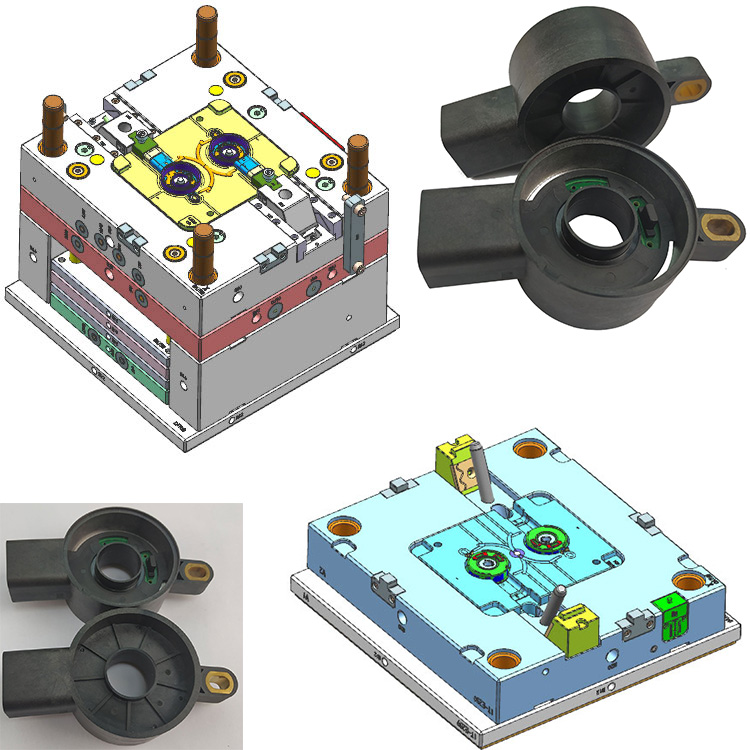

Plastic Mold Injection Molding

Generally, plastic mold injection molding consists of several basic parts

The specific components of the process for making the structure of plastic molds are as follows: Generally speaking, there are two main types of plastic molds: one is the two plate mold, commonly known as the large water mouth mold; The alternative is the three board mold, commonly known as the fine water mouth mold. Whether it is a two board mold or a three board mold, plastic molds generally consist of the following parts:

1. Mold frame. In plastic molds, the mold frame constitutes the most basic frame part of the plastic mold. The steel quality of the mold frame can ensure the service life of a set of molds. Stability in post production.

2. The core part of a plastic mold - the cavity and core. The main cavity and core of a plastic mold, commonly known as the mold core or inner mold, are the most important components inside the mold. Most of the design work is also spent on the design of the mold core, which involves deep mechanical processing of the mold core in the finished product. However, some relatively simple molds do not have a mold core part, and products are directly formed on the template, especially in the early days of plastic molds, which have been gradually phased out. There are many material classifications for mold cores, including imported steel and domestically produced national standard steel.

3. Auxiliary parts for plastic molds, such as positioning rings, sprue sleeves, push rods (also known as top rods or top pins), material pulling rods (commonly known as grabbing pins), support columns, ejector plate guide columns and sleeves, and support nails (commonly known as garbage nails). If it is a three plate mold, a specialized sequential mold opening control mechanism is often required.

4. Auxiliary systems for desired material molds. Generally, plastic molds have the following three systems: pouring system, ejector system, and cooling system. Sometimes, because the plastic materials used require high heating temperatures, some molds also have a heating system.

5. When some plastic molds have holes or hooks in the lateral direction when producing plastic products, the mold must also be equipped with one or more mechanisms to handle the demolding of these holes and hooks, such as sliders, inclined push rods, hydraulic cylinders, etc. This type of processing mechanism is called a lateral parting core pulling mechanism.