Analysis of Sheet Metal Processing Technology

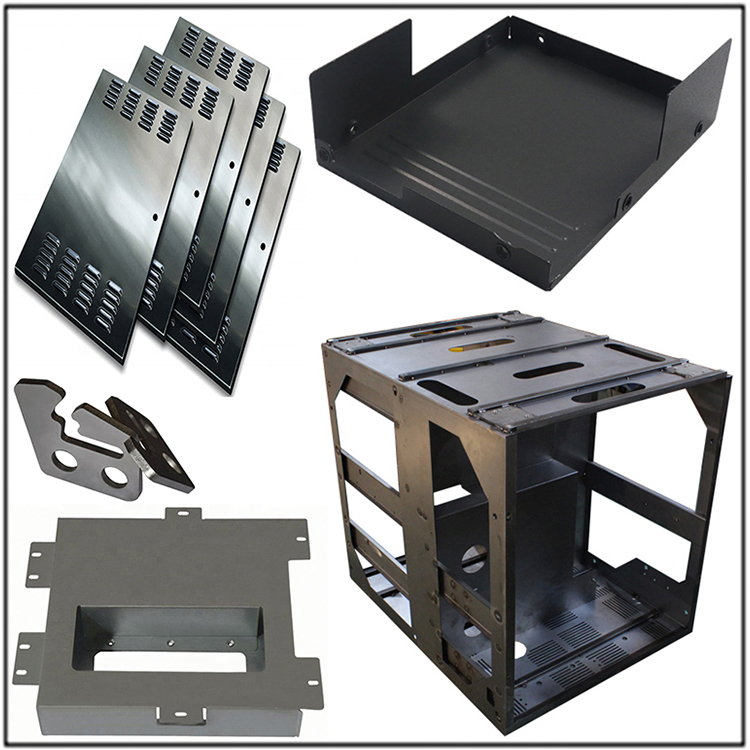

Sheet metal processing technology refers to the process of transforming metal raw materials into required parts or products through mechanical equipment such as presses and shearing machines. The sheet metal processing technology usually includes the following steps: design, cutting, bending, stamping, welding, spraying, etc.

Firstly, there is the design phase. According to customer requirements and drawings, sheet metal processing enterprises need to conduct detailed design and process analysis. The quality of the design process is directly related to the smooth progress of subsequent processes, so careful analysis and evaluation are needed.

Next is cutting. Cutting refers to cutting metal raw materials according to a certain size based on the design drawings. The quality of cutting is directly related to processing accuracy and material utilization, so it is necessary to use appropriate cutting equipment and processes.

Then there's the bending. Bending is the process of bending a metal sheet according to design requirements to form the desired shape. Bending requires the use of specialized bending machines, and different bending effects can be obtained by adjusting the parameters of the machine and the shape of the mold.

Stamping refers to the impact deformation of metal sheets according to a certain shape and size. Stamping can be used to create holes, concave convex shapes, etc. The stamping process requires the use of stamping machines, and by selecting appropriate punches and dies, different shapes of stamped parts can be achieved.

Welding is the process of connecting multiple sheet metal parts by heating or applying pressure. Welding can be used to connect sheet metal parts of different shapes, as well as to repair damaged sheet metal parts. The welding process requires the use of welding equipment, and the appropriate welding method should be selected according to different sheet metal parts and welding requirements.

Finally, there is spraying. Spray coating is the process of applying a layer of paint onto the surface of sheet metal parts to protect and beautify them. The spraying process requires the use of spraying equipment, and by selecting appropriate coatings and spraying methods, different spraying effects can be obtained.

In summary, sheet metal processing technology is a multi-step process that requires precise design and appropriate equipment to complete. Different processing steps have different process requirements, and it is necessary to choose the appropriate process according to the specific situation. The optimization of sheet metal processing technology can improve processing efficiency and product quality, reduce production costs, and is of great significance to sheet metal processing enterprises.