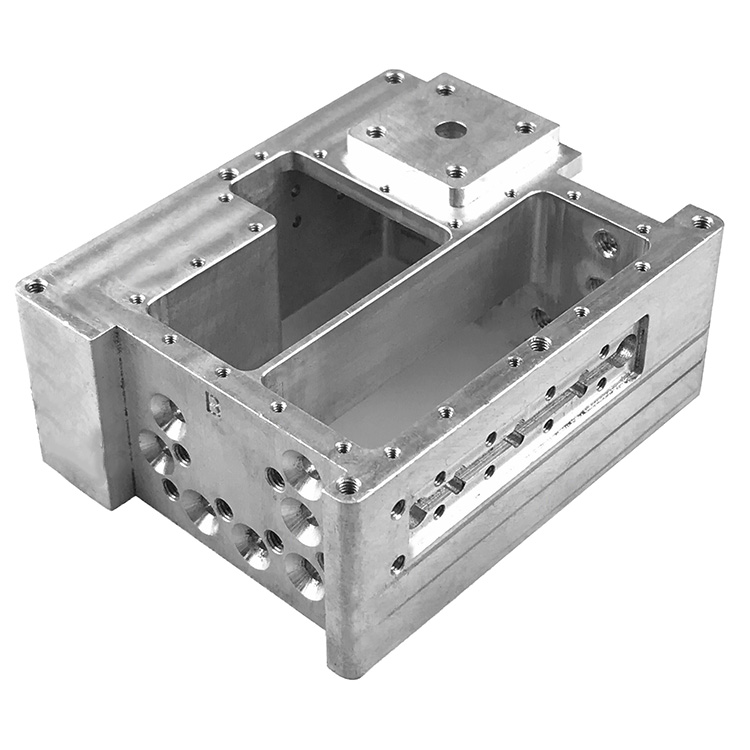

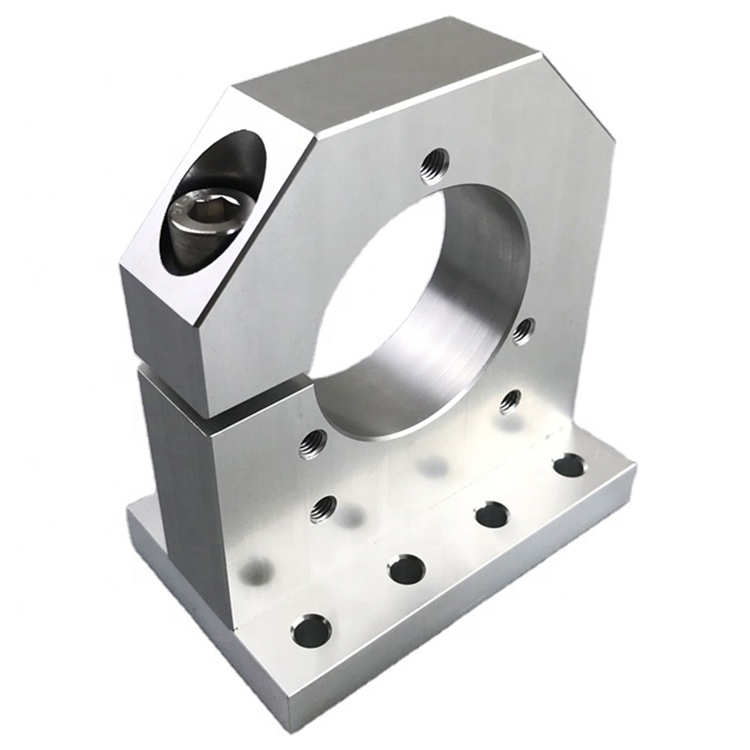

CNC Machining Parts Technology

What impact does precision CNC machining technology have on industry

When there is no precision machinery, traditional machining methods used by machining manufacturers not only affect the production speed of parts, but also significantly reduce the manufacturing quality of components. But we know that efficiency and quality are the foundation of a company's survival, especially when small and medium-sized enterprises increase their order volume, the production volume must also reach a considerable standard. At present, only precision machining can meet this standard in society. Precision machining of mechanical parts relies on advanced manufacturing technology, high-efficiency, and high-precision automated production equipment to complete it. Therefore, equipment allocation is the first priority.

Precision CNC parts machining technology is a process that specifies the machining process and operation mode of parts. Under specific production conditions, the reasonable process and operating methods are written into process documents in the prescribed form, which are approved and used to guide on-site production. The process flow of precision machining technology parts generally includes the process route of part processing, the specific content and equipment used in each process, the inspection items and methods of parts, the rated time and cutting quantity, etc.

There are many advantages to precision machining of parts, which can effectively improve production volume and efficiency, have considerable feed efficiency, and reduce enterprise costs. Precision manufacturing and processing technology can also improve working conditions, shorten labor time, reduce labor intensity, and enhance the level of civilized production. In addition, precision machining can reduce more personnel configuration and site rent, shorten production cycles, reduce costs, and save energy. Therefore, the application of precision machining technology has many benefits.