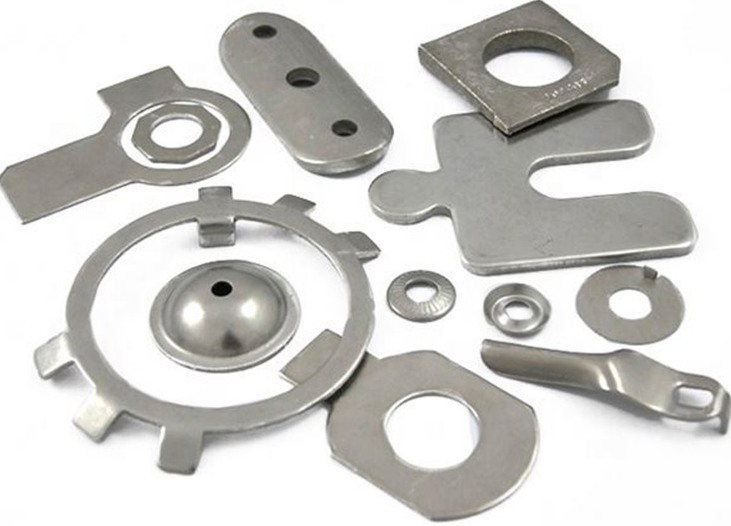

Manufacturing Process of Precision Metal Stamping Parts

Detailed explanation of the manufacturing process of precision metal stamping parts

The manufacturing process of precision metal stamping parts is a complex and delicate process involving multiple key steps. The following is a detailed introduction to the process:

1,Material preparation

Material selection: The material selection for precision metal stamping parts is crucial, and commonly used materials include low-carbon steel, stainless steel, aluminum and aluminum alloys, copper and copper alloys, etc. These materials should have good plasticity, weldability, and mechanical properties to ensure the quality of stamped parts.

Material pretreatment: Before stamping, materials usually need to be pretreated, such as cutting, cleaning, leveling, etc., to ensure the quality and dimensional accuracy of the material.

2,Mold design

Design principle: Mold design should follow the principles of simple structure, easy operation, safety and reliability. At the same time, it is necessary to consider factors such as the plastic deformation law of the material, the magnitude and direction of the impact force, and the wear of the mold.

Mold material: High quality alloy tool steel, such as Cr12MoV, is usually selected as the mold material to ensure the hardness, machinability, and wear resistance of the mold.

3,Stamping forming

Stamping process:

Punching process: including cutting, punching, cutting, trimming, tongue cutting, slicing, etc., used to manufacture various shapes of flat parts.

Bending process: a stamping process that involves bending, rounding, twisting, etc., to bend materials into a certain angle and shape.

Stretching process: such as deep drawing and thinning deep drawing, used to manufacture open hollow parts or other shaped hollow parts.

Forming process: including flipping, flanging, bulging, necking, expanding, undulating, sizing, etc., used to manufacture stamped parts with various spatial curved shapes.

Parameter control: During the stamping process, it is necessary to strictly control parameters such as stamping force, stamping speed, and stamping stroke to ensure the forming quality and accuracy of the parts.

4,Post processing

Deburring: Removing sharp protrusions on the surface of parts to prevent stress concentration and wear during use.

Cleaning: Remove oil stains and impurities from the surface of the parts to ensure their cleanliness.

Heat treatment: Adjusting the organization and properties of materials to improve the strength and hardness of parts.

Surface treatment: such as spraying, electroplating, etc., to enhance the corrosion resistance, aesthetics, and service life of parts.

5,Quality inspection

Dimensional measurement: Use measuring tools to accurately measure the dimensions of parts to ensure compliance with design requirements.

Appearance inspection: Check the surface quality of the parts, such as flatness, smoothness, etc.

Metallographic analysis: Conduct metallographic analysis on parts to examine their internal structure and material properties.

Summary: The production process of precision metal stamping parts involves multiple key steps such as material preparation, mold design, stamping forming, post-processing, and quality inspection. Each step requires strict control and precise operation to ensure high precision, high quality, and high performance of the stamped parts.