What is The Process of Precision Metal Stamping Parts Processing?

Precision metal stamping processing is a technology that uses precision molds and advanced processes to punch or stretch metal sheets and strips. This technology mainly includes four main processing techniques: punching, bending, deep drawing, and local forming.

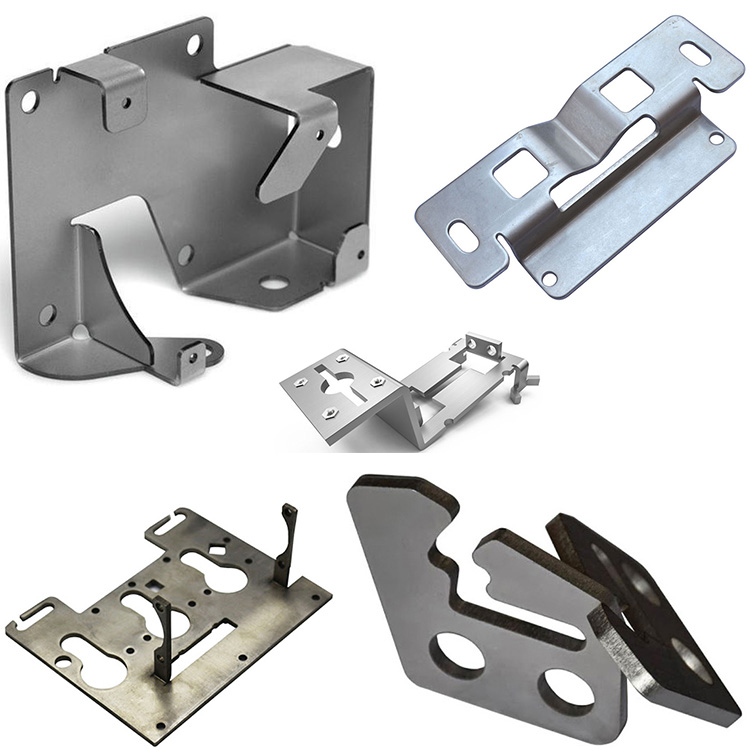

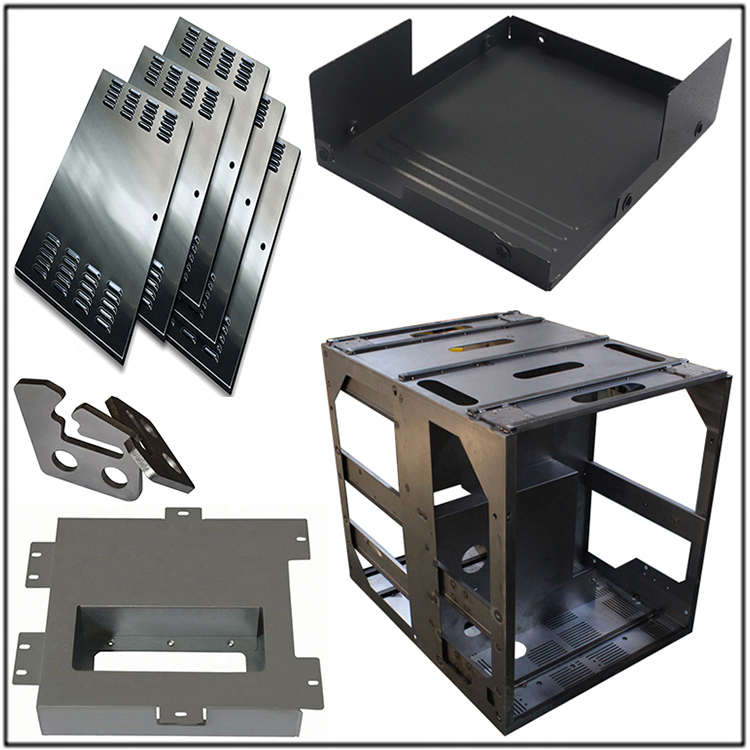

Punching: It is a stamping process that separates sheet metal, including punching, cutting, trimming, and sectioning. During this process, the metal sheet can be precisely cut and separated using a mold to obtain the desired shape of the part.

Bending: It is a stamping process that bends sheet metal into a certain angle and shape along a bending curve. This step is mainly used to manufacture metal stamping parts with curved or complex shapes.

Deep drawing: It is a stamping process that transforms flat sheet metal into various open hollow parts, or further changes the shape and size of hollow parts. This step is particularly important when manufacturing cavities or hollow parts with complex internal structures.

Local forming: It is a stamping process that uses various types of local deformations to change the shape of the blank or stamped part, including flanging, bulging, leveling, and shaping processes.

The main types of precision metal stamping processing include cold stamping, warm extrusion, and hot stamping. Among them, cold stamping is the most widely used technology, accounting for about 80% of the entire production process.

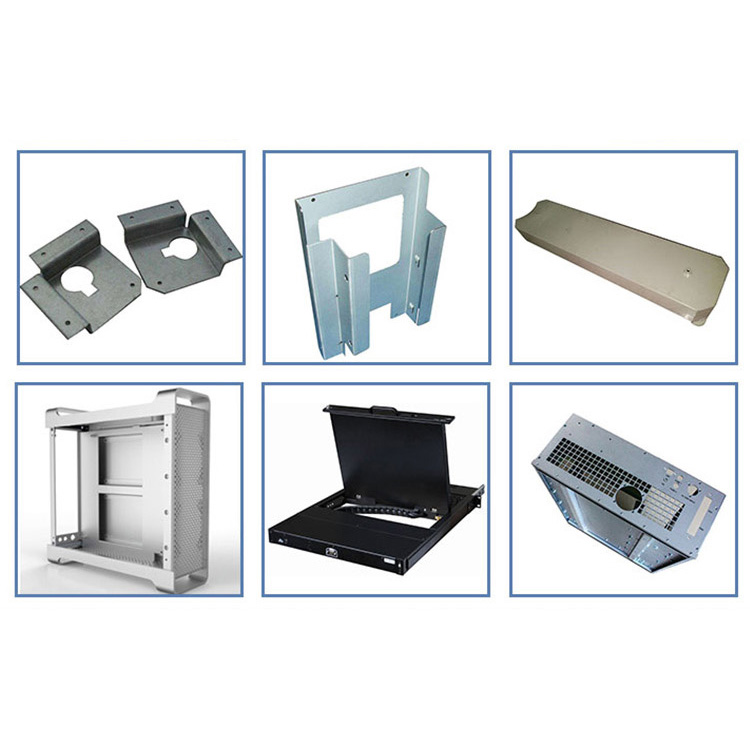

Precision metal stamping processing has a wide range of applications in various industries, such as the automotive industry, home appliance industry, electronic communication, construction and decoration, and lighting industry. For example, the body panels, doors, engine hood, etc. of automobiles are all produced through precision metal stamping processing.

In addition, in order to process precision metal stamping parts, specialized equipment such as punching machines and molds are required. These devices require high precision and stability to ensure that the processed metal stamping parts have precise dimensions and shapes. At the same time, strict quality control is required during the processing, including inspection and repair steps, to ensure that the quality and performance of the product meet the requirements.