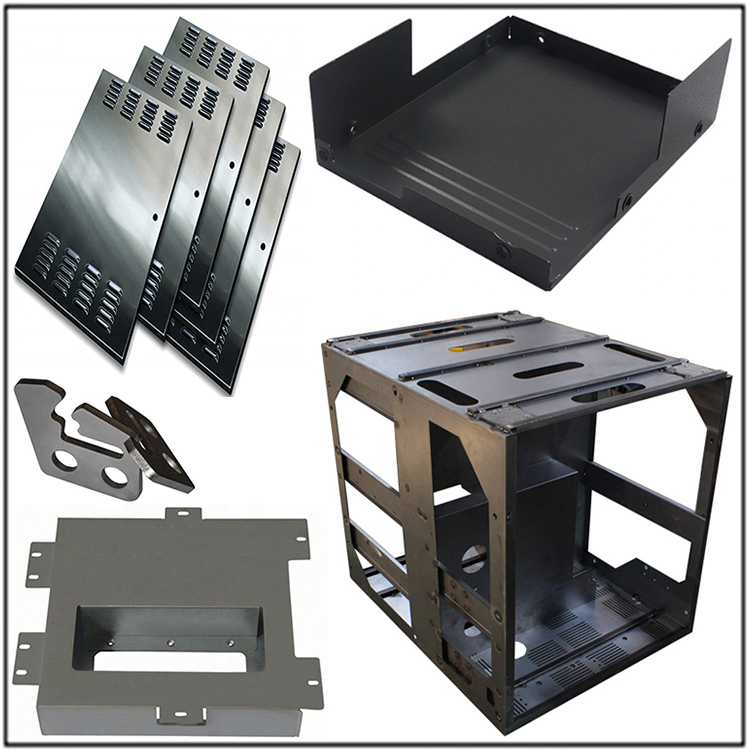

Precision Stretch Metal Parts:The Combination of Good Materials and Fine Craftsmanship

Precision stretching parts are important components widely used in the engineering field, playing a crucial role in fields such as automotive manufacturing, aerospace, and electronic equipment. They are usually made of high-quality materials through precision machining, with excellent mechanical properties and accurate size control, providing reliable support and guarantee for various engineering projects.

The manufacturing process of precision stretching parts requires the selection of good materials. Generally, high-strength and corrosion-resistant metal materials such as stainless steel, aluminum alloy, and titanium alloy are common choices. These materials have good processability and mechanical properties, which can meet the strength, durability, and stability requirements of various engineering projects for tensile parts.

Secondly, the manufacturing of precision drawn parts requires precise processing techniques. Stretching parts are usually achieved through processes such as cold stamping, hot stamping, cold drawing, or hot drawing to achieve shape changes and size control. In this process, precise mold design and processing are required to ensure the dimensional accuracy and surface quality of the stretching parts. At the same time, appropriate heat treatment, surface treatment and other processes are needed to improve the strength, hardness and corrosion resistance of the stretched parts.

Precision stretching parts have multiple advantages. Due to its precise manufacturing process, it has highly consistent dimensions and shapes, ensuring interchangeability and fit during assembly. Secondly, due to the selection of good materials and precise processing techniques, it has excellent mechanical properties such as high strength, high hardness, and good toughness, which can meet the requirements of various complex engineering projects. In addition, precision stretching parts also have good corrosion resistance and stability, and can be used for a long time in harsh environmental conditions.

Precision stretching parts have a wide range of applications in various fields. In the field of automobile manufacturing, they are used for connecting and supporting components such as engines, bodies, and chassis; In the aerospace field, they are used in the manufacturing of aviation components such as airplanes and spacecraft; In the field of electronic devices, they are used for the assembly and connection of electronic products such as mobile phones and computers. It can be said that precision stretching parts are an indispensable and important component in the field of modern engineering, providing solid technical support and guarantee for the successful implementation of various engineering projects.

In summary, precision stretching parts have become important components in the engineering field due to their good materials and fine craftsmanship. They have excellent mechanical properties and stability, and are widely used in fields such as automotive manufacturing, aerospace, electronic equipment, etc., providing reliable support and guarantee for the smooth implementation of various engineering projects. With the continuous development and progress of technology, we believe that precision stretching parts will play a more important role in the future and make greater contributions to the development and progress of the engineering field.