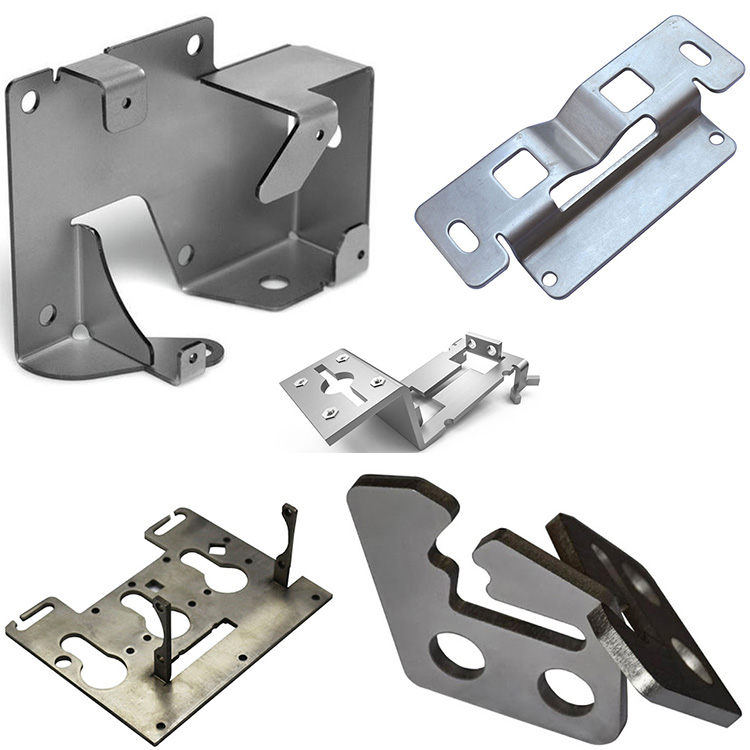

Sheet Metal Stamping Parts is An Important Component of Modern Industrial Manufacturing

Sheet metal stamping parts are a common component in modern industrial manufacturing, widely used in fields such as automobiles, home appliances, aerospace, etc. This article will introduce the definition, manufacturing process, application fields, and importance of sheet metal stamping parts in industrial production.

1.Definition

Sheet metal stamping parts are components made by stamping, bending, forming and other processes on metal sheets. They typically have complex shapes and structures that can meet various engineering design requirements, and have high precision and surface quality.

2.Manufacturing process

The manufacturing process of sheet metal stamping parts mainly includes the following steps:

Design and Mold Manufacturing: First, based on the product design requirements, develop a design plan for sheet metal parts and manufacture the corresponding stamping molds.

Material preparation: Select appropriate metal sheets as raw materials and carry out cutting, forming, and pretreatment processes.

Stamping forming: Place a metal sheet on a punch press and impact it with a punch to form the desired shape along the contour of the mold.

Bending, welding, and assembly: The process of bending, welding, and assembling stamped parts to form sheet metal stamping parts.

Surface treatment: Surface treatment of finished products, such as spraying, plating, etc., to improve their corrosion resistance and aesthetics.

3.Application Fields

Sheet metal stamping parts are widely used in the following fields:

Automotive industry: As an important component of automotive body, doors, engine hood and other parts, sheet metal stamping parts play a key role in automotive manufacturing.

Home appliance industry: In the manufacturing of home appliances such as washing machines, refrigerators, air conditioners, etc., sheet metal stamping parts are often used for the production of components such as shells and panels.

Aerospace field: Sheet metal stamping parts are also an indispensable and important component in the manufacturing of aerospace components such as aircraft and rockets.

Electronic communication: Sheet metal stamping parts are widely used in the production of components such as casings and screen frames in electronic products such as mobile phones, computers, and other devices.

4.Importance

As an important component of modern industrial manufacturing, sheet metal stamping parts have the following significant meanings:

Improve production efficiency: Stamping technology can achieve rapid batch processing of metal sheets, improving production efficiency and speed.

Reduce production costs: Compared with traditional casting, forging and other processes, the manufacturing process of sheet metal stamping parts is simple and has good processability, which can reduce production costs and material waste.

Enhance product quality: Stamping technology can ensure the accuracy and consistency of parts, improving product quality and reliability.

Promoting product innovation: The manufacturing process of sheet metal stamping parts is flexible and diverse, which can meet the design requirements of complex shapes and structures, promoting product innovation and development.