The Process Characteristics of CNC Prototype

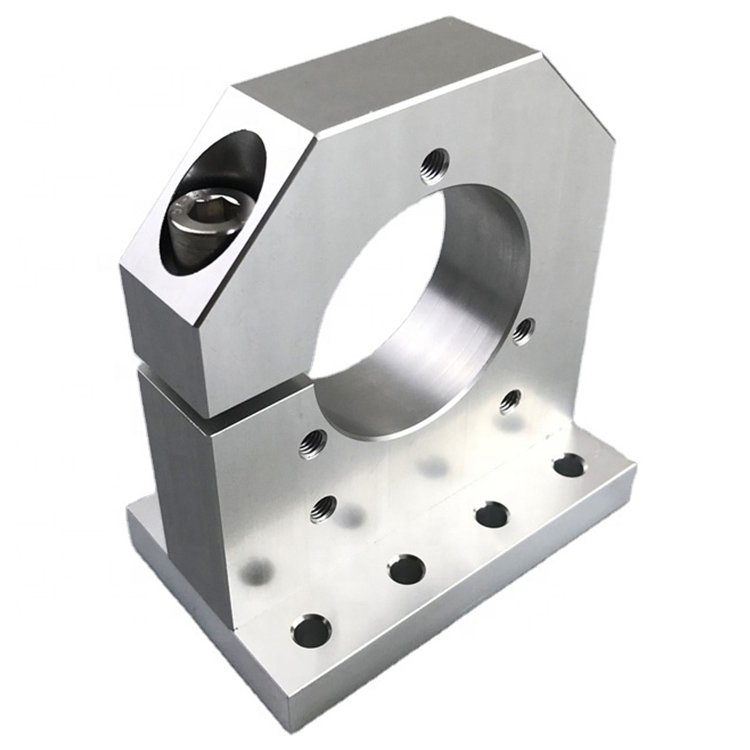

CNC prototype is a traditional machining method that removes excess material from the entire material through a removal method. In the manual panel processing industry, CNC prototype factories generally target large workpieces and exterior panels. Easy to use, such as ABS PMMA. Bohm PC. Yaki (transparent material), etc. The cost of CNC prototype is low, and the processed materials have characteristics such as high strength, high temperature resistance, high toughness, transparency, etc. It can also be made into metal prototype such as aluminum alloy.

In addition, the surface treatment of CNC prototypes is diverse, such as grinding and spraying dust, painting, polishing, screen printing, electroplating, etc., and its effect can be compared with products produced by molds. In terms of appearance, assembly, functional verification, etc., it can achieve the customer's final design intention, therefore, CNC prototyping has become the mainstream processing mode of modern manual machining. There are significant differences between CNC machining of prototype and CNC machining of steel. The CNC machining is a workpiece that can truly reflect the customer's design intention, while the CNC machining steel mold is only one side, namely the front and rear molds, and the process is complex and cumbersome.

CNC prototype processing is commonly used for mobile phones PDA、 Digital cameras, small household appliances, and electronic computer peripherals. It can also manufacture large and complex product functional testing standard parts, such as air conditioners, televisions, electronic keyboards, displays, speakers, medical equipment, motorcycles, automotive parts, and other products.

Analysis of CNC Prototype Materials

ABS prototype: Temperature resistance: 60-80 ℃/Characteristics: Strength/toughness: General/Scope of application: Electrical shell prototype

PMMA sub power board: temperature resistance: 60-80 ℃/characteristics: high transparency, low strength/toughness/application: LCD shell prototype.

POM steel plate: temperature resistance: 90-110 ℃/characteristics: strength, toughness, hardness/applicable range: mechanical gears, rotating parts.

PC: Temperature resistance: 90-110 C/D: semi transparent, hardness, strength, toughness/General use: rice cooker, electric iron, high heat part, manual board.