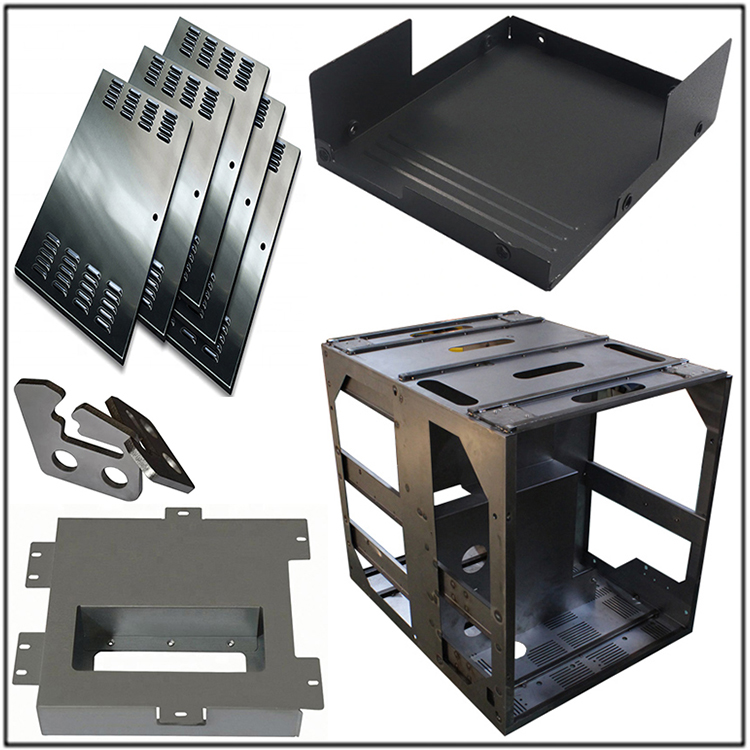

What are The Advantages of Precision Stamping Parts Processing

There are several advantages to precision stamping processing compared to traditional methods, including:

1.Stamping processing has high production efficiency, simple operation, and is easy to achieve mechanization and automation. This is because stamping processing relies on stamping dies and stamping equipment to complete the processing. The punching speed of ordinary punching machines can reach dozens of times per minute, while high-speed punching machines can reach hundreds or even thousands of times per minute, and each punching can result in a stamped part. Hongao Precision has more than ten years of experience in mechanical processing, with a high-quality processing team and suppliers in the mechanical industry. Add WeChat to the picture for quotation.

2.The die ensures the size and shape accuracy of the stamping parts, generally does not damage the surface quality of the stamping parts, and the life of the die is generally long, so the quality of the stamping parts is stable, the interchangeability is good, and the stamping parts are "identical".

Stamping can process parts with a wide range of sizes and complex shapes, such as stopwatches for clocks, longitudinal beams for cars, and car coverings. In addition, the cold deformation and hardening of materials during the stamping process result in higher strength and rigidity of the stamping.

Generally speaking, stamping does not produce chips or waste, so the consumption of materials is relatively low and no other heating equipment is required.