The Compatibility of Injection Plastic Parts Assembly?

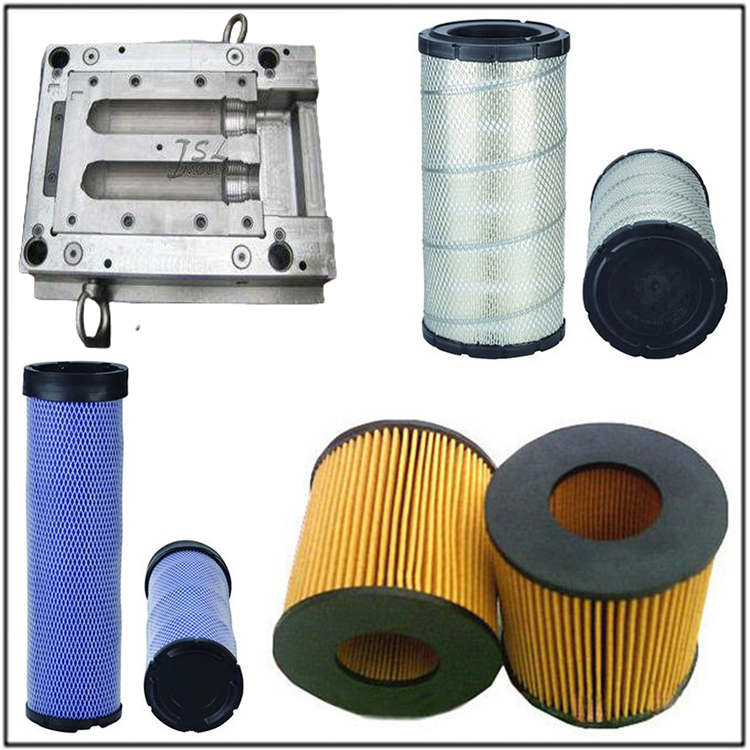

In modern industrial production, the application of injection molded parts is ubiquitous. From electronic products to automotive components, from daily necessities to medical equipment, injection molded parts play a crucial role. However, while focusing on the quality, cost, and production efficiency of injection molded parts, a key factor is often overlooked - the compatibility of injection molded part assembly. How important is the assembly compatibility of injection molded parts?

Imagine if you are producing a precision electronic product, where each component needs to be perfectly assembled together to perform its intended function. If the assembly compatibility between injection molded parts is poor, it may lead to gaps, looseness, or even inability to assemble the product. This not only affects the appearance and quality of the product, but may also reduce its performance and reliability, and even affect the user experience. So, how to improve the assembly compatibility of injection molded parts?

Firstly, in the design phase, it is necessary to fully consider the issue of assembly compatibility. Designers should design the size, shape, and structure of injection molded parts reasonably based on the functionality and usage requirements of the product, ensuring that each component can fit tightly together.

Secondly, when choosing injection molding materials, material compatibility should also be considered. Different materials may have different physical and chemical properties, and if the materials are incompatible, it may cause deformation, cracking, and other problems in the assembly process of injection molded parts.

In addition, process control during the production process is also crucial. Strictly controlling parameters such as injection temperature, pressure, and speed can ensure the dimensional accuracy and surface quality of injection molded parts, thereby improving assembly compatibility. In addition to the above points, there are also other factors that can affect the assembly compatibility of injection molded plastic parts. For example, storage and transportation conditions for injection molded parts, temperature and humidity in the assembly environment, etc.