How to Ensure The Perfect Delivery of Each Injection Molded Plastic Parts?

In the injection molding industry, product quality is the key for enterprises to establish themselves in the market. Whether it is household appliances, automotive parts, or electronic product casings, customers have increasingly high quality requirements for injection molded products. So, how can injection molding factories ensure that every product leaves the factory in perfect condition? This article will reveal the key points of injection molding quality control from multiple perspectives

1.The quality of injection molded products starts from the raw materials. High quality plastic pellets, masterbatch, and additives are the foundation for producing high-quality products. When purchasing raw materials, injection molding factories will strictly screen suppliers and conduct quality inspections on each batch of raw materials to ensure that they meet production standards. Meanwhile, reasonable storage conditions and management of raw materials are also important factors in ensuring their performance.

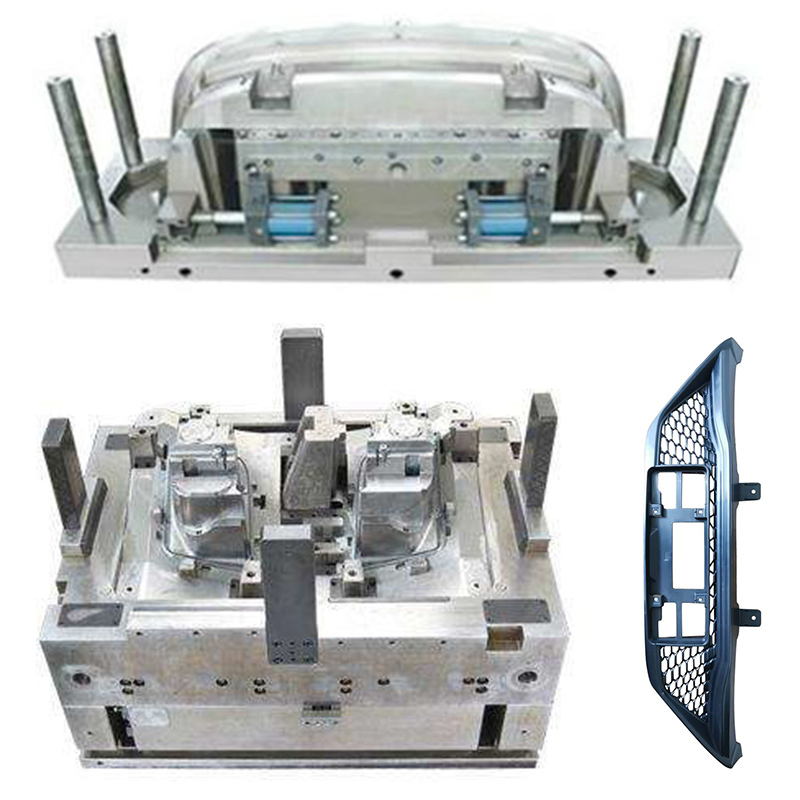

2.Mold is the soul of injection molding technology. The design and manufacturing accuracy of molds directly determine the size, shape, and surface quality of products. In order to ensure that each product meets the standards, injection molding factories use advanced mold manufacturing technology and equipment, and conduct repeated testing and adjustment to ensure the accuracy and durability of the molds. In addition, regular maintenance and upkeep of molds are also important measures to avoid defects in production.

3.In injection molding, the control of equipment performance and process is crucial. Modern injection molding factories are typically equipped with highly automated production equipment, which not only improves production efficiency but also ensures consistent quality of each product through precise temperature, pressure, and time control. Meanwhile, the real-time monitoring system can detect and adjust various process parameters during the production process to prevent quality issues from occurring.

4.In order to ensure that every product can be perfectly manufactured, the injection molding factory will conduct strict quality inspections at all stages of production. Common detection methods include size measurement, visual inspection, functional testing, etc. For some high demand products, special physical performance tests will also be conducted, such as impact resistance tests, high temperature resistance tests, etc.

5.Injection molding factories not only need to pay attention to the quality of each product, but also need to improve the overall production level through refined production management and continuous improvement. Through data analysis and feedback mechanisms, factories can promptly identify and correct production problems, continuously optimize process flows, reduce defect rates, and improve production efficiency.

6.In injection molding, ensuring the perfect delivery of each product is not an easy task, as it requires excellence in every aspect from raw materials to finished products. If you have more interest in quality control of injection molding process, please continue to follow us. We will bring you more professional and practical industry information.