In the field of plastic product production, the quality of plastic molds is crucial. It directly affects the accuracy, appearance, and production efficiency of the product. So, how to accurately determine the quality of plastic molds? Below is a detailed introduction for you.

1.Appearance inspection

Firstly, observe the appearance of the plastic mold. The surface of high-quality plastic molds should be smooth and flat, without obvious scratches, pits, and rust. The parting surface should be clear, neat, and free of burrs and burrs. The identification and numbering of the mold should be clearly visible for easy management and maintenance. For example, if there are many scratches on the surface of the mold, it may cause defects on the surface of the product during the production process, affecting the appearance quality of the product.

2.Dimensional accuracy

Use high-precision measuring tools, such as coordinate measuring instruments, to measure the key dimensions of plastic molds. The dimensional accuracy of the mold should meet the design requirements, and the tolerance range should be controlled within a reasonable range. For example, for some precision plastic product molds, extremely high dimensional accuracy is required, and even a slight deviation may cause the product to be unable to be assembled or used properly.

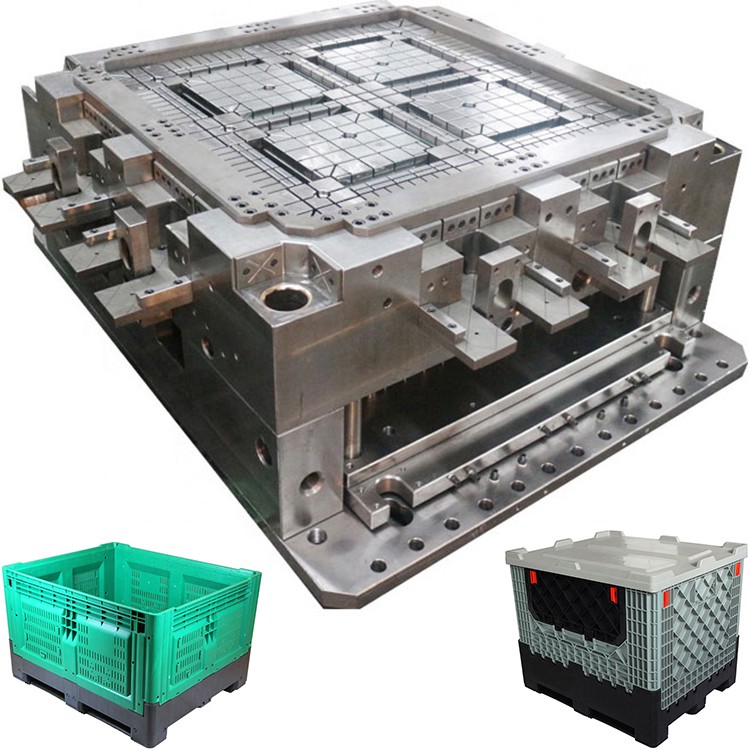

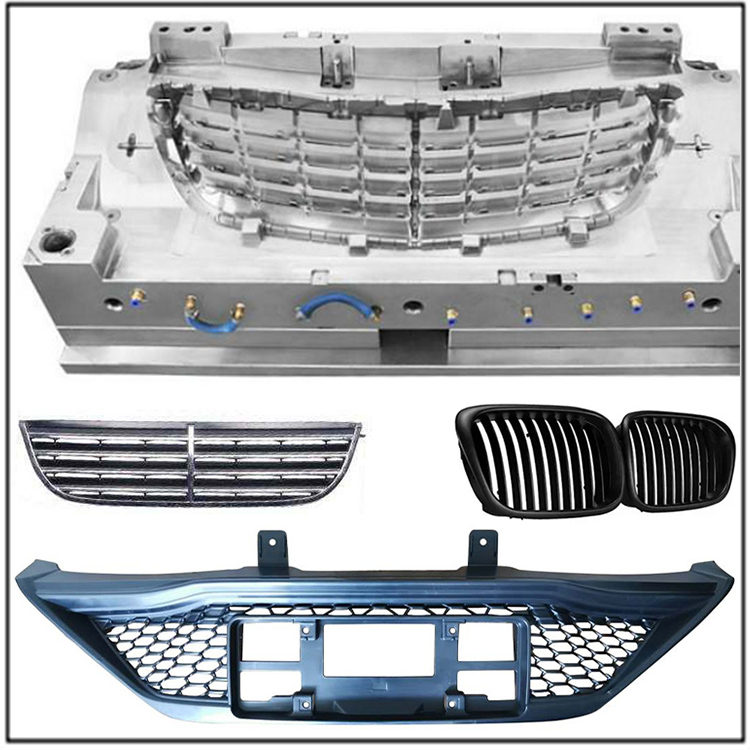

3.Structural rationality

Evaluate whether the structure of plastic molds is reasonable. The structure of the mold should be easy to demold, and the flow channel design should be smooth to ensure that the plastic can evenly fill the mold cavity. The cooling system should be evenly distributed to effectively control the mold temperature and prevent product deformation. Taking injection molds as an example, if the cooling system design is not reasonable, it may lead to uneven cooling of the product, resulting in defects such as warping.

4.Material quality

Understand the materials used in the mold. High quality mold materials have good wear resistance, corrosion resistance, and high strength. Common mold materials such as P20, 718, etc. For example, using low-quality mold materials may cause wear and tear in a short period of time, affecting the service life of the mold and product quality.

5.Trial mold effect

Conducting trial molding is an important step in inspecting the quality of plastic molds. Observe the products produced by the trial mold to see if there are defects such as insufficient filling, flying edges, bubbles, shrinkage, etc. The dimensional stability and consistency of the product are also important indicators for judging the quality of the mold. By repeatedly testing the mold and analyzing and improving the problems that arise, the quality of the mold can be continuously optimized.