Do You Know the Ten Techniques for Plastic Mold Processing?

Plastic mold processing is an important manufacturing process that plays a crucial role in many fields. Mastering some key skills and methods can improve the processing quality and efficiency of plastic molds. This article will introduce you to the top ten techniques for plastic mold processing, helping you better understand and apply them in practical processing.

Catalogue

1. Choose appropriate materials

2. Design a reasonable mold structure

3. Reasonably control mold parameters

4. Fine machining of mold surface

5. Control of injection molding temperature

6. Control injection molding cycle

7. Choose appropriate injection molding equipment

8. Mold maintenance and upkeep

9. Prevention and Solution of Avoiding Problems

10. Continuous learning and innovation

1,Choose appropriate materials

1.1 Characteristics and Applicability of Different Plastic Materials

1.2 Choose appropriate plastic materials

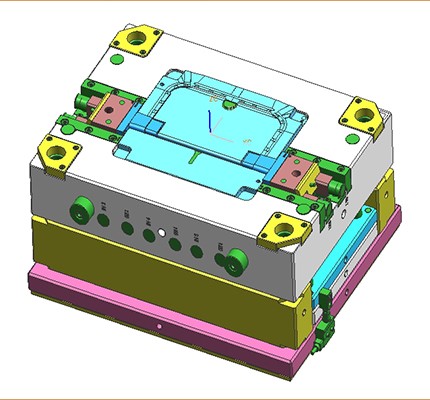

2,Design a reasonable mold structure

2.1 Design that focuses on product resilience and strain

2.2 Considering the disassembly and assembly of molds

2.3 Reasonably determine the layout of the cooling system

3, Reasonably control mold parameters

3.1 Control mold dimensions and tolerances

3.2 Design a reasonable mold dispensing system

3.3 Choose the appropriate cooling time

4, Fine machining of mold surface

4.1 Understanding and Choosing Different Surface Treatment Methods

4.2 Cleaning the surface of the mold

4.3 Use appropriate lubricants

5,Control of Injection Temperature

5.1 Pay attention to the melt temperature

5.2 Control mold temperature

5.3 Reasonable adjustment of cooling system

6,Control injection molding cycle

6.1 Optimizing injection molding process parameters

6.2 Pay attention to the control of injection molding speed and pressure

6.3 Reasonably setting the injection molding cycle

7, Choose appropriate injection molding equipment

7.1 Prudent selection of injection molding machine styles and specifications

7.2 Understand the operating points of the injection molding machine control system

7.3 Learn to use and maintain injection molding machinery and equipment

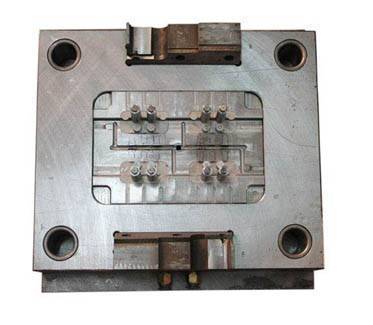

8, Mold maintenance and upkeep

8.1 Regular inspection and cleaning of molds

8.2 Timely repair and replacement of damaged components

8.3 Maintain the stability and durability of the mold

9,Prevention and Solution of Avoiding Problems

9.1 Analysis and solutions to common problems

9.2 Track the operation status of the mold and promptly handle any abnormalities

9.3 Promoting Quality Improvement through Mold Improvement

10,Continuous learning and innovation

10.1 Pay attention to the development of new technologies and materials in the industry

10.2 Participate in training and exchange activities

10.3 Continuously Attempting Innovation and Improvement

Summary:

By selecting appropriate materials and designing reasonable mold structures, controlling mold parameters and finely processing mold surfaces, controlling injection temperature and cycle, and selecting appropriate injection equipment, we can maintain and maintain molds, prevent and solve problems, and continuously learn and innovate. Only then can we better master the completion techniques of plastic mold processing and continuously improve processing quality and efficiency in practical applications.