Plastic Gear Injection Molding Technology

Plastic Gear Injection Molding Technology: Principles, Applications, and Development Prospects | Rainbowmold Ltd

Plastic gear injection molding technology is an efficient and precise manufacturing process in modern industrial production. Through this technology, we can produce plastic gears with complex shapes and superior performance, which are widely used in various mechanical equipment and electronic products. This article will delve into the principles, process flow, and application fields of plastic gear injection molding technology, aiming to provide readers with a comprehensive analysis of the mystery and value of this technology.

1,Overview of Plastic Gear Injection Molding Technology

Plastic gear injection molding technology uses an injection molding machine to inject molten plastic material into a mold, which is then cooled and solidified before demolding to obtain the desired shape of the plastic gear. This technology has the advantages of high production efficiency, high product accuracy, and low cost, thus it has been widely used in industrial production.

2,Plastic gear injection molding process flow

The process flow of plastic gear injection molding mainly includes the following steps:

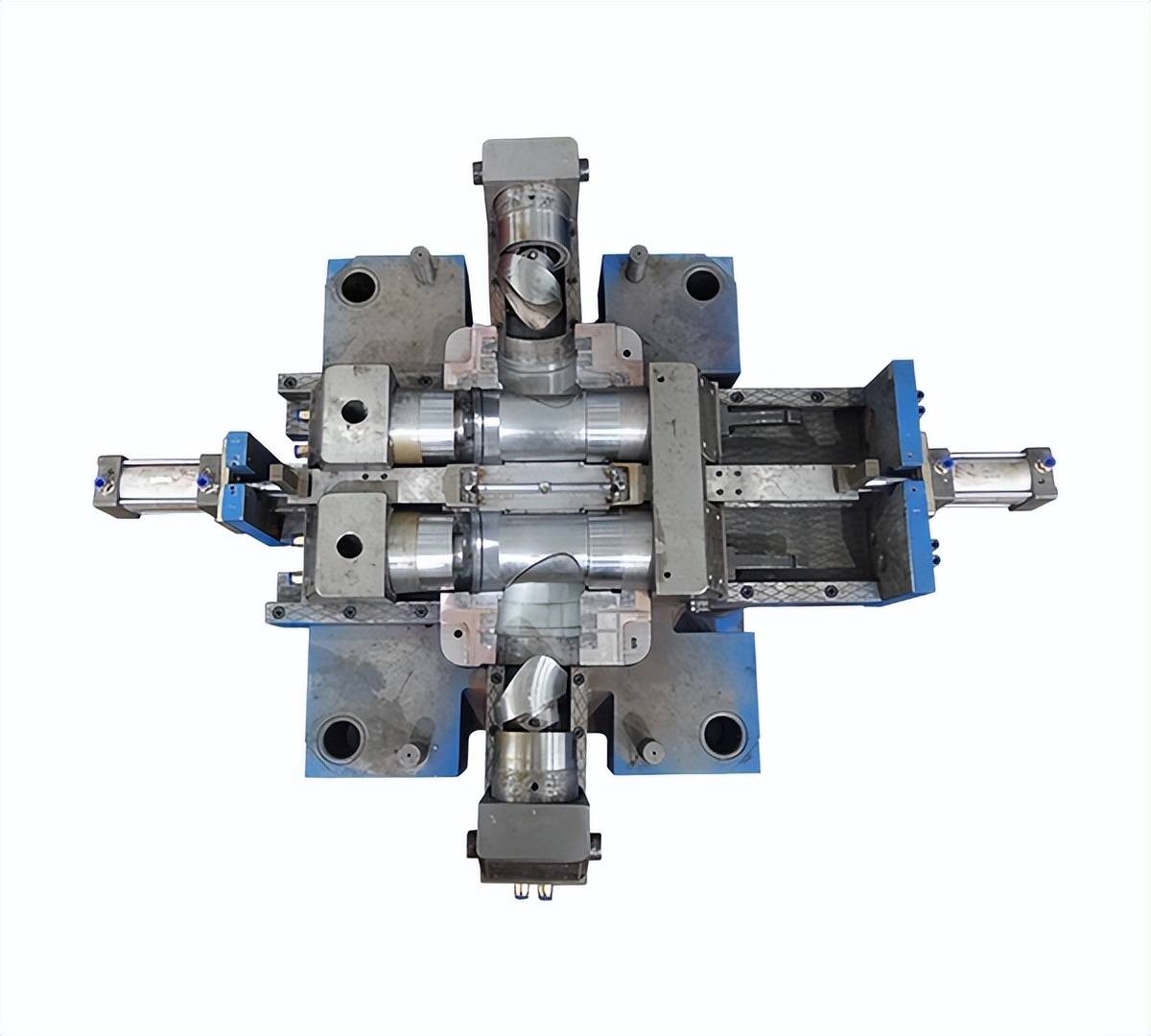

Mold design and manufacturing: Design and manufacture corresponding injection molds based on the shape and size requirements of plastic gears.

Material preparation: Select suitable plastic materials and perform pre-treatment such as drying, color matching, etc.

Injection molding machine operation: Inject molten plastic material into the mold, control parameters such as injection pressure, speed, and temperature to ensure the quality of plastic gear molding.

Cooling and solidification: Cool the plastic gear in the mold to solidify it into shape.

Demolding and post-treatment: Remove the plastic gear from the mold and perform necessary post-treatment, such as polishing, painting, etc.

3,The advantages of plastic gear injection molding technology

The plastic gear injection molding technology has the following advantages compared to other manufacturing processes:

High production efficiency: Injection molding technology can achieve automated production, greatly improving production efficiency.

High product accuracy: Through precise mold design and injection molding machine operation, plastic gears with complex shapes and high precision can be produced.

Low cost: Injection molding technology can achieve large-scale production and reduce the cost of unit products.

4,Application fields of plastic gear injection molding technology

Plastic gear injection molding technology is widely used in various industrial fields, especially in mechanical equipment and electronic products. For example, the transmission system in the automotive manufacturing industry, the reduction device in household appliances, and the transmission mechanism in office equipment all rely on the application of plastic gears. In addition, with the continuous development of technology, the application of plastic gears in fields such as robots and automation equipment is becoming increasingly widespread.

Summary:

Plastic gear injection molding technology, as an efficient and precise manufacturing process, plays an important role in modern industrial production. By gaining a deeper understanding of its principles, process flow, and application areas, we can better utilize this technology to promote the progress and development of industrial production. In the future, with the continuous innovation of materials science and manufacturing technology, plastic gear injection molding technology will usher in broader development prospects.