What are the Advantages and Disadvantages of Using Aluminum Alloy Material CNC to Process Parts

There are many advantages and disadvantages to using aluminum alloy materials for CNC machining and manufacturing parts. Here are some of the main advantages and disadvantages:

Advantages:

Lightweight and high-strength: Aluminum alloy has excellent strength to weight ratio, so the manufactured parts are usually very light, but still have sufficient strength, suitable for various applications, especially in the aerospace and automotive industries.

Superior thermal conductivity: Aluminum alloy has excellent thermal conductivity, which helps parts dissipate heat under high temperature conditions and is suitable for applications that require heat dissipation performance, such as electronic devices and engine components.

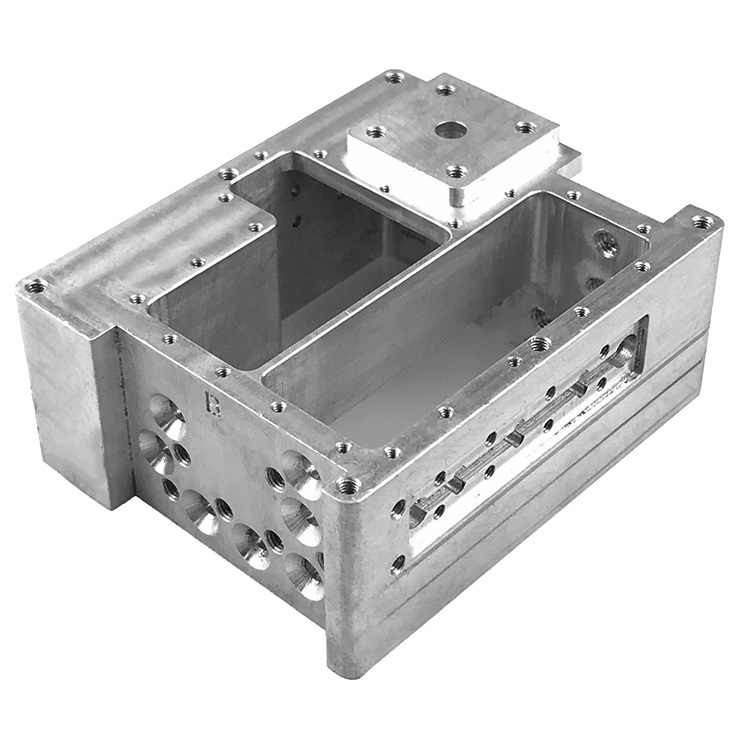

Easy to process: Aluminum alloy is relatively easy to process and is suitable for CNC machining and other mechanical processing techniques. It can generate complex geometric shapes and high-precision parts.

Corrosion resistance: Aluminum alloys typically have good corrosion resistance, especially when they have undergone appropriate surface treatment.

Recyclability: Aluminum alloy is a recyclable material that helps reduce environmental impact and minimize waste.

Cost effectiveness: Compared to some other metal alloys, aluminum alloys are usually more economical, making them a cost-effective choice for manufacturing parts.

Disadvantages:

Low melting point: Aluminum alloys have a relatively low melting point, which may limit their use in high-temperature applications.

Low hardness: Compared to some other metals, aluminum alloys have lower hardness and may not be suitable for applications that require high strength and wear resistance.

Easy to scratch: Aluminum alloy has low scratch resistance and may be susceptible to scratches and wear.

Oxidation problem: Untreated aluminum alloys may easily oxidize, forming an oxide layer that requires surface treatment to improve oxidation resistance.

Conductivity limitation: Although aluminum has good thermal conductivity, its electrical conductivity is poor, making it unsuitable for certain applications that require good conductivity.

Taking all factors into consideration, aluminum alloy is a commonly used manufacturing material that is suitable for many application fields. However, when selecting, it is necessary to weigh its advantages and disadvantages based on specific needs and performance requirements. In CNC machining, aluminum alloy is usually a popular choice because it is easy to machine and has high strength and lightweight performance.