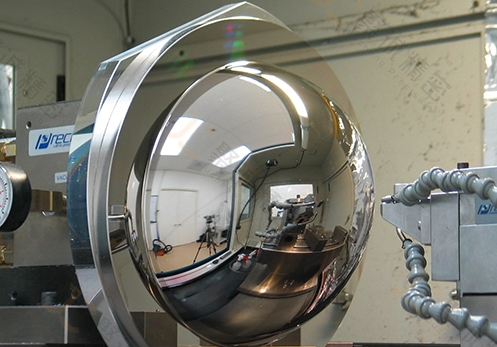

Mirror Finish CNC Machining Aluminum Alloy Parts

How to achieve mirror finish in CNC machining of aluminum alloy?

To make aluminum alloy parts into mirror surfaces, multiple steps are required, including pretreatment, processing, polishing, and cleaning. The following is a detailed explanation:

Material preparation:

Choose high-quality aluminum alloy materials to ensure surface smoothness and quality.

Clean the workspace to ensure there is no dust, dirt, or impurities.

CNC machining:

Use CNC machine tools for rough machining of aluminum alloy parts to cut out their shapes.

Choose appropriate cutting tools and cutting parameters to achieve a smooth surface.

Surface flatness inspection:

Use a surface roughness measuring instrument to check the flatness of aluminum alloy parts.

Correct any flatness issues, such as high cutting or uneven surfaces.

Polishing pretreatment:

Before performing mirror polishing, perform rough and medium grinding to remove defects, reduce roughness, and prepare for polishing work.

Use sandpaper, grinding tools, and abrasives to improve surface quality.

Mirror polishing:

Use a mirror polishing machine and high-purity polishing paste to start mirror polishing.

First, perform rough grinding, then gradually transition to medium and fine grinding until the desired mirror effect is achieved.

Perform cross grinding to avoid the formation of scratches and abrasions.

Pay attention to maintaining appropriate pressure and speed to ensure uniform polishing.

Cleaning and inspection:

Clean aluminum alloy parts to remove polishing paste and debris.

Use clean water or solvent, then blow dry with dry air.

Carefully inspect the surface of the parts to ensure there are no defects or stains.

Protective coating:

To protect the surface of the mirror, appropriate protective coatings such as varnish or oxide film can be applied.

Mirror polishing is a tedious and highly technical process that typically requires specialized equipment and experienced operators. To achieve better results, multiple polishing and inspections are usually required to ensure a completely smooth and mirror like surface.